Ideal for High Speed Planters / Variable Rate Side Dressing

When it comes to todays high speed planters, the AgXcel GX30 VRT solution addresses the wider range of application requirements. Going from 3MPH to 12 MPH is one thing, but while maintaining consistent application rates & pump pressure is crucial. The GX30 completely manages operational pressures which increases application accuracy and a greater range of flow rates.

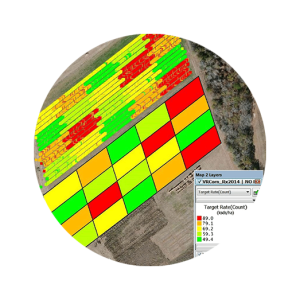

Prescription Based Application

Your prescription based application fields are no longer limited. With the AgXcel GX30 VRT, you can now apply at a variable rate the right way. Whether its planting infurrow, 2×2, side dressing, the GX30 VRT will allow you to set and forget your rate!

Rate Changes on the Fly

The AgXcel GX30 VRT allows you to manage the required field GPA rate on the fly. When conditions or decisions change between fields, the GX30 VRT can be changed on the fly at any time. When one field required 5GPA and then another field requires 8 GPA, you can apply with confidence using the GX30 VRT.

The AgXcel GX30 VRT allows you to manage the required field GPA rate on the fly. When conditions or decisions change between fields, the GX30 VRT can be changed on the fly at any time. When one field required 5GPA and then another field requires 8 GPA, you can apply with confidence using the GX30 VRT.

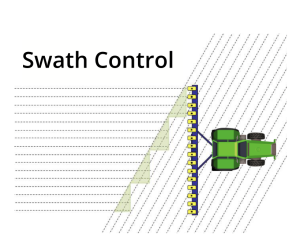

Swath Control

The GX30 has the ability to be configured for swath control. Setup the swath according to your requirements. No longer are you stuck to one configuration. Each row has the ability to become a section, all depending on your field requirements.

Key Features:

- Dual Micro Control Valves:Utilizes two dual micro control valves per row, allowing seamless shifting between Microtubes to maintain optimal system pressure.

- OEM Agnostic Compatibility:Can operate independently of your current setup and is compatible with various agricultural equipment brands.

- CANBUS Valves/ISOBUS Integration:Uses CANBUS valves to control each row individually, eliminating the need to manually check valves on each row. Manage the GX30 VRT from the Virtual Terminal on your existing ISOBUS monitor.

Key Benefits:

– Stable System Pressure: The dual micro valve setup ensures stable liquid system pressure, promoting greater application accuracy and reducing wear on pumps typically caused by high pressure.

– Enhanced Efficiency: Enables quicker application startup at the beginning of each pass, optimizing operational efficiency in the field.

– Precision Application: Maintains precise application rates across varying conditions, enhancing crop health and yield potential.

The GX30 VRT from AgXcel integrates advanced technology to streamline liquid fertilizer application, offering farmers a reliable solution to manage rates effectively while improving overall operational performance.

The AgXcel GX30iVRT benefits:

The AgXcel GX30 VRT addresses this issue with the ability to broaden this range by implementing a 3 stage orifice range system. Exhaustive testing at AgXcel has established the critical benefits of a 3 option orifice system.

- A 3 system orifice setup with our Dual Body micro valve setup allows for a much broader range of application both at higher rates and at lower rates.

- 2 orifice sizes are selected, one for the lower and one for the upper range.

- The 3rd orifice is created by allowing both micro valves to open which combines the lower and upper range into a dual application ratio, allowing for a much broader range.

- AgXcel also uses our GX6 Microtubing technology to size the application range with 11 different sizes, for solutions that are viscous or have high particle content.

- The micro valves control the flow at all rows and creates an instant “shut off” point therefore preventing system pressure loss when the liquid system goes into hold mode.

- The most common plumbing setups today use check valves to prevent “drain out” when the system goes into hold. System pressure will drop down to the check valve pressure setting. So if you have 4lb check valves, system pressure will drop down to approximately 4 psi if not lower.

- With the micro valve system, pressure is maintained when the valve is shut.

- This pressure maintaining feature results in a quicker application start when the system goes back into start mode. The liquid system does not have to build pressure back to it delivering rate which in turn causes start points not to have fertilizer placement until enough pressure is in the system to open up the check valves.

- Lower GPA rates are also achieved at lower PSI ratings. Since there is no longer a check valve that has to open after system pressure is built, with the micro valves, they are either flowing or not flowing. This means, even if system pressure reduces to 2PSI, liquid will still be flowing at the appropriate rate since no pressure is required to open a rated check valve.

- The dual micro valves now serve as the liquid systems “sectional valves”. Therefore, there no longer is the need to run exhaustive amounts of 3/4” feed hose throughout the implement.

- Implementing the dual micro valves on each row allows for a more responsive application when the system goes from hold position to run.

Explore Products

- Request your hassle free quote now!

- AgXcel YouTube

- Order by Phone: +1 (877) 218-1981